1932

1932 was a year of great change. Amelia Earhart became the first woman to fly over the Atlantic. The BBC started television broadcasting. The Sydney Harbour Bridge opened to the public. The first Venice Film Festival was held.

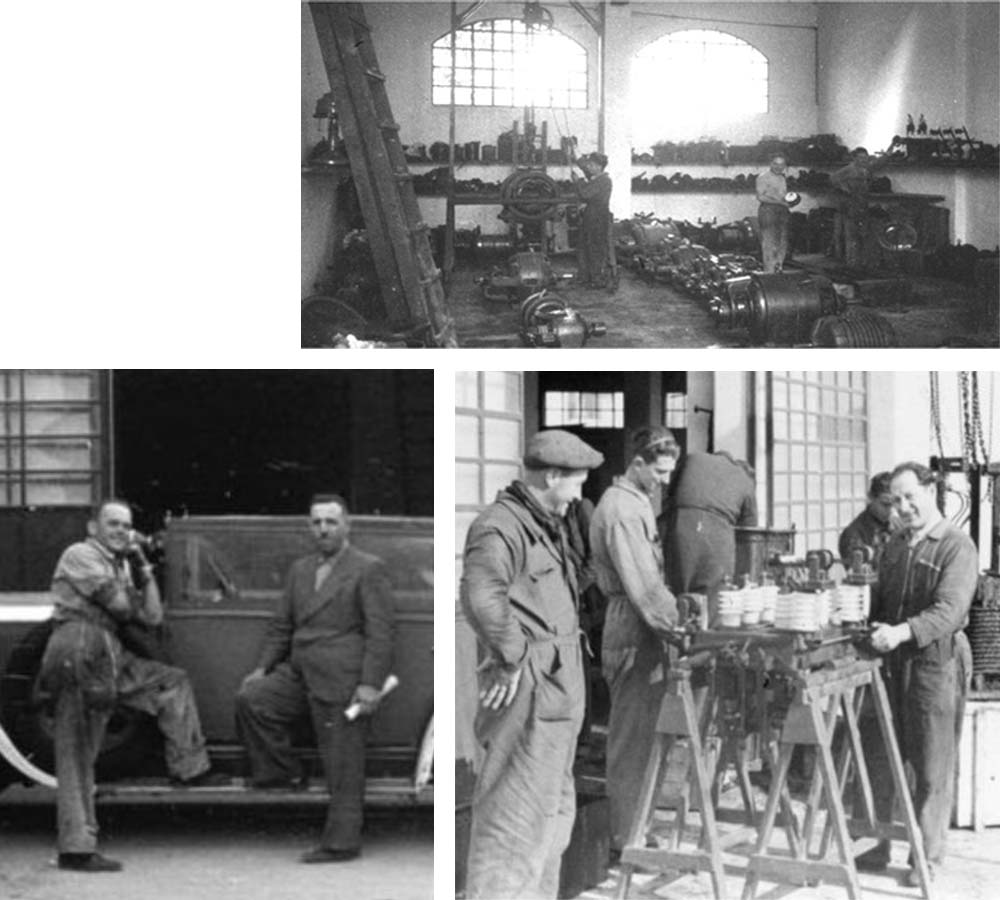

That year, one change did not make the headlines. A 25-year-old Italian man, Ettore Varisco, quit his job at the Padua branch of SGIV to start his own business as an electrical engineer. He obtained a contract to service electric motors, alternators, dynamos and transformers at the company where he previously worked. As work increased, he also started selling and converting electromechanical components. From the very beginning, Varisco was ready for change.

1940s

The 1940s were difficult times. World War II dashed many hopes, exacting a heavy price in terms of human lives. The whole world was changing. Ettore Varisco approached those times with entrepreneurial flair. To make up for the shortage of oil products, he began producing gas generators for cars and tractors. Not only that: he also started producing and selling the necessary coal to fuel the generators.

A first example of a “one stop shop”.

1948

Those were the years of great reconstruction and frenetic activity. Italy, reduced to a pile of rubble, offered the market absolutely nothing new. Varisco resourcefully continued on his way, recycling and then selling useful material left behind in Italy by the allied troops.

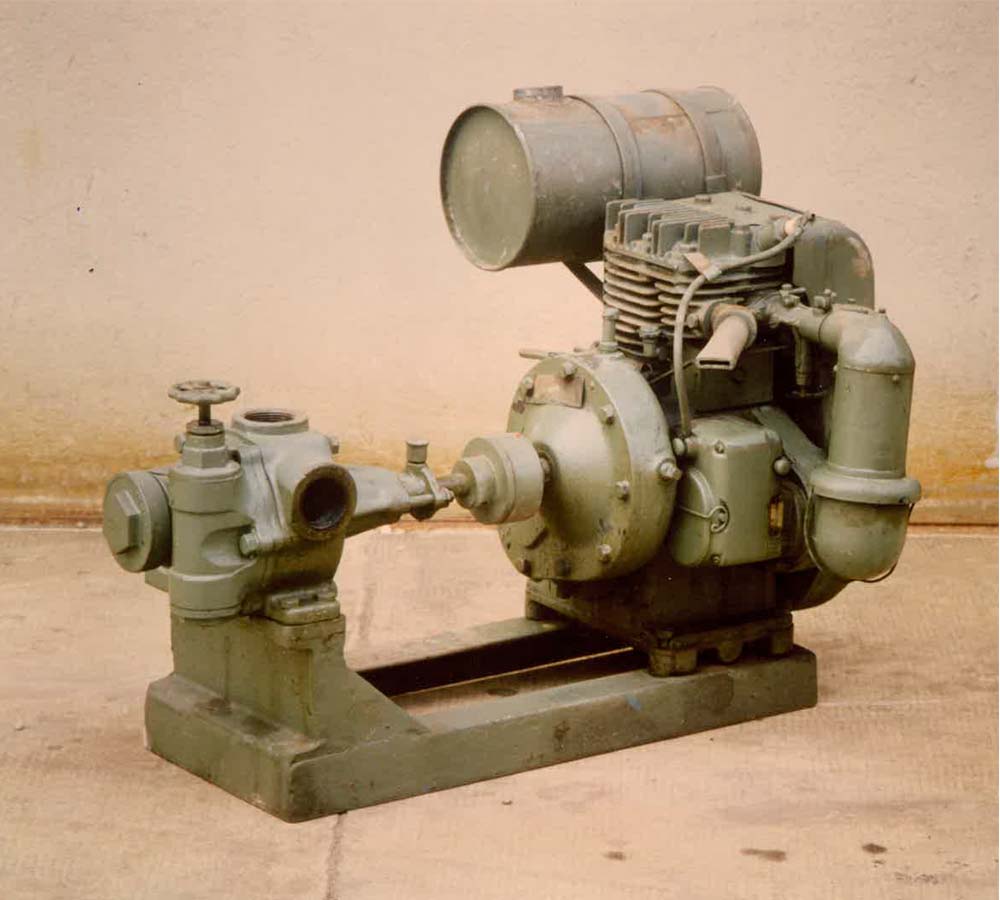

One commodity in particular was clamoured for: pumps. Pumps were useful in industry, construction and agriculture. In 1948, the stock ran out, although demand continued relentlessly. The concept of “Market Orientation” had not yet been invented, but in response to pressing demands from its customers Varisco decided to start building pumps.

Thus, in 1948, the first 4″ self-priming centrifugal pump, named “Jonio 100”, was born. This name derives from the Italian sea bearing the same name, and the “J” is still stamped on our pumps today.

1950s

1950 was the year of the Schuman Declaration, the first important step towards the creation of the European Union. The foreword reveals the spirit in which the proposal to create the European Coal and Steel Community was made: “World peace cannot be safeguarded without the making of creative efforts proportionate to the dangers which threaten it.” In that same year, Varisco made a major creative effort by starting the production of gear pumps to expand the range to be offered to industries. Vertical axis pumps and high-pressure water pumps were also produced.

1960s

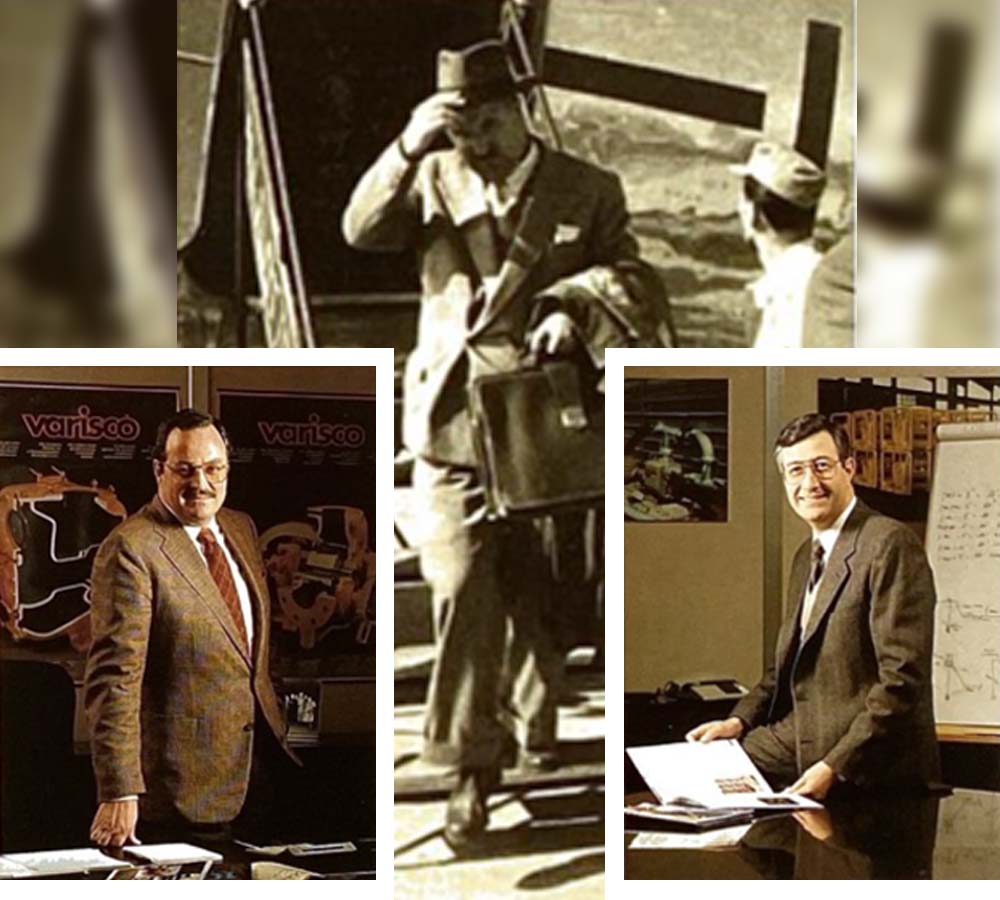

In the early 1960s, Ettore Varisco was succeeded by his sons Vittorio and Giuseppe (or Pino) Varisco.

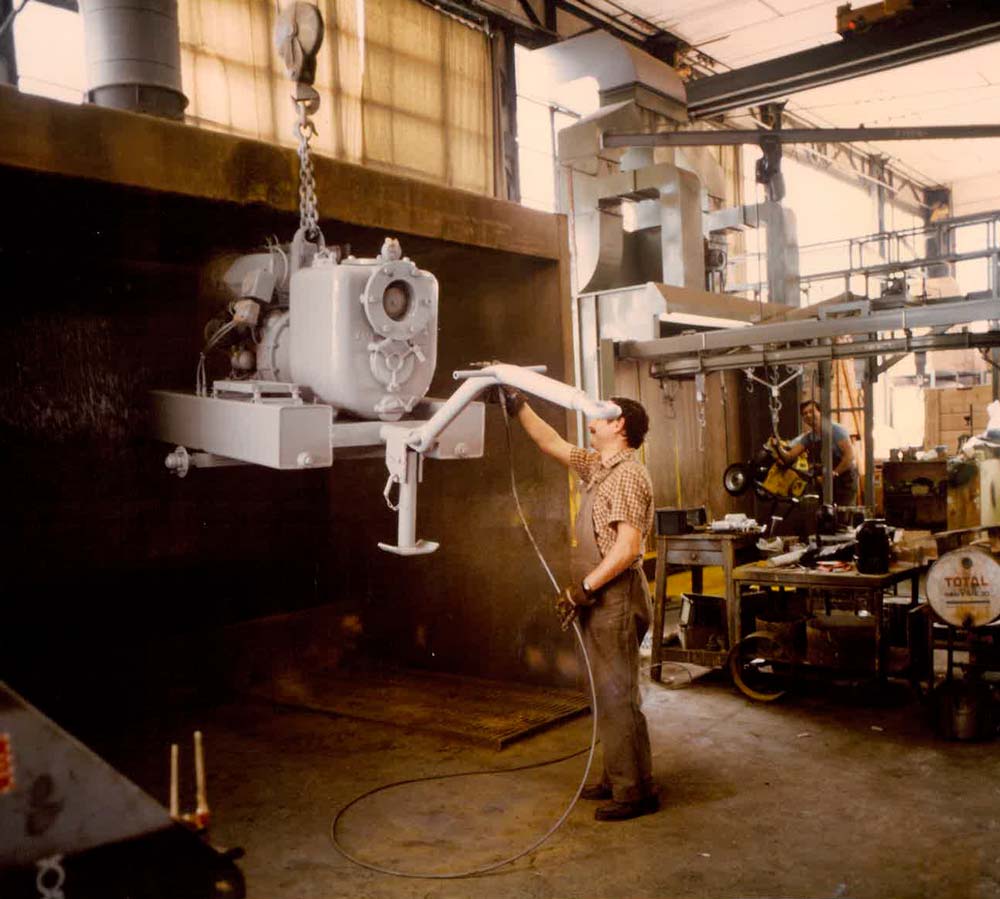

During these years, the world underwent further changes. Many countries gained independence from colonial powers, man flew into space and set foot on the moon. Varisco continued to grow at a fast pace: before long, the workshop in the Stanga area of Padua proved too small. Industrial zones sprang up in various parts of Italy and in 1965 the company moved to Via Terza Strada in Padua. It was another brave move, as it required a considerable investment, but it provided large spaces to store the wellpoint equipment for lowering the water table on site, adding new services to production. The synergies meant a lot: on-site comparisons and customer feedback proved to be valuable tools for product development and helped make reliability a top priority.

1972

1972 was the year of President Nixon’s historic visit to the People’s Republic of China. In those very days, newspapers recounted the first flight of the European Airbus. By now, Varisco was an established name in Italy: it was time to look further.

Hanging in the executive offices was a map of Italy: you could also see parts of Austria and Germany as far as Munich. It seemed the ideal place to start exporting: another country, but on the same map as Italy! Thus Varisco visited the BAUMA trade fair in Munich, exploring the pump market outside Italy for the first time. Contacts from that fair led to the formation of a subsidiary in Germany in 1974. From then on, foreign markets became increasingly important for Varisco.

1977

Steady and balanced growth, as Varisco’s was, cannot be achieved by chance: it requires patience, planning and investment. Constantly straining the financial resources of a family-run business, Varisco purchased transfer machine tools in 1977, the year “Star Wars” was produced and smallpox disappeared, before installing the first numerically controlled “machining centres” in 1982, the year Italy won the World Cup in Spain. New and valuable space was gained by installing a vertical warehouse with 1872 containers in 1985.

Varisco’s growth continued unabated, until he occupied all available spaces. The rental market grew along with pump production, to the point where a new company, Varisco Wellpoint, was created.

1988

Inauguration of the new office building in Via Terza Strada, 9, a 1500 square metre building among the most beautiful in the industrial area of Padua.

“The office building that we are inaugurating today is nothing more than a symbol of what lies behind it: the beautiful façade of a structure that has been consolidated over a long period of time”.

Pino Varisco

1990s

In the 1990s, Varisco decided to implement the SAP information system for production, sales and administration. Varisco was one of the first medium-sized companies to adopt an ERP system designed for much larger and more complex companies. Full software integration with the automated warehouse was achieved through the cooperation of another German company, Klumpp Informatik. The work done for Varisco became a case study for them, useful for many other companies.

2000s

All over the world, the new millennium started off with parties and fireworks. Varisco prepared for Y2K by moving stocks to the new warehouse and working to ensure the factory was fully operational in January. A new factory, a new computer system, a new set of codes and assembly lists: each of these changes alone can take months, if not years, before they work properly. However, thanks to careful planning and patience combined with customer understanding they were implemented in a fraction of the time normally required.

2008

Cina and USA

In 2008, the production and sales hub in TianJin, China, was established. The plant is involved in the production of bare shaft and trolleyed pumps, commercially serving the mainland China and SEA area. Over the years, important milestones were achieved that made Varisco a leading brand in the emergency drainage market and industry in China.

The same year the sales office opened in the USA – initially at our long-standing distributor Thompson Pumps (Florida) and later with its own headquarters in Charlotte (North Carolina) with a large pump storage warehouse and sales offices. The headquarters also contributed to the expansion of the Varisco brand in the American market by taking part in national trade fairs and industry events.

2016

A breakthrough occurred in January 2016. Varisco joins Atlas Copco, the Swedish group listed on the Stockholm Stock Exchange that specialises in providing industrial productivity solutions. The company was revolutionised by dividing the commercial core from the production core under the Customer Centre and Product Company respectively, while the product portfolio was split between the industrial division, under the Varisco brand, and the drainage division, under the Atlas Copco brand. From this moment on, the market becomes global thanks to the group’s distribution power, and drainage product ranges are developed and expanded thanks to huge investments.

The headquarters moved to the current address: Via Prima Strada, 37.

In the meantime, at the rate of at least one new model per year, the new drainage pump offer has taken shape, built in a completely renovated factory.

2022

On the 90th anniversary of the Varisco brand, the sale of Industria products, which until then had been handled exclusively by the Customer Centre in Padua, was also entrusted to other European Customer Centres.

At the same time, the group decided to invest heavily in R&D to renew its range of internal gear pumps.